Product Highlights

| Interface: | Circuits: | Configurations: |

|---|---|---|

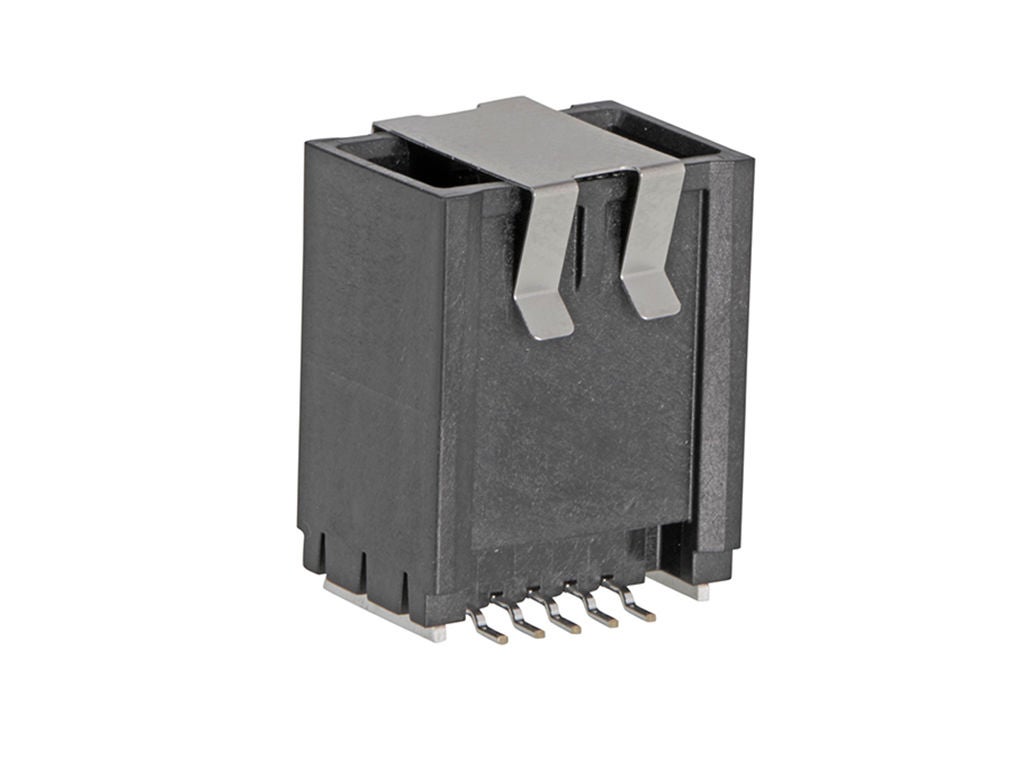

| Arbeitskreis (AK) | Single row: 2 to 6 circuits Dual Row: 10 and 22 circuits (8 and 20 when used with a CPA) | Right Angle, Vertical SMT |

Features and Benefits

Overview

Marketplace demands are leading automotive OEMs to include more infotainment and safety options in their vehicles. As a result, space constraints are a growing issue as designers need to fit additional electronics in the same real estate. ConnTAK50 Connectors offer a compact 1.80mm pitch for the dual-row version, easing space constraints.

Some tier 1 automotive suppliers have a need for a vertical SMT header. However, few connector manufacturers offer this configuration for automobile applications. The ConnTAK50 Connector System includes a vertical SMT header which enables automated assembly.

The AK interface and terminal are common in the European automotive marketplace. Therefore, connectors that are mate-able with this interface and can house AK terminals are in demand. ConnTAK50 Connectors have been designed with both the AK interface and cavity. As a result, they are mate-able with existing AK connectors and can be used with AK terminals. Therefore, the ConnTAK50 Connector is a drop-in replacement for existing competitor AK connectors.

Applications by Industry

Battery Management Systems (BMSs)

Bluetooth

Camera modules

HVAC

In-vehicle switches

Lighting

Seat/Mirror control

This is not a definitive list of applications for this product. It represents some of the more common uses.

?ts=1707783808137&dpr=off)

?ts=1707783808161&dpr=off)